Mixing Tank Height Diameter Ratio . apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. Taller vessels, with aspect ratios ranging to. to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t) off center. standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w , clearance of. 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. tanks with a 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. 1/6 th will provide a stronger vortex, 1/4 th will.

from www.sielmann-tank.com

to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w , clearance of. Taller vessels, with aspect ratios ranging to. 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t) off center. tanks with a 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. 1/6 th will provide a stronger vortex, 1/4 th will.

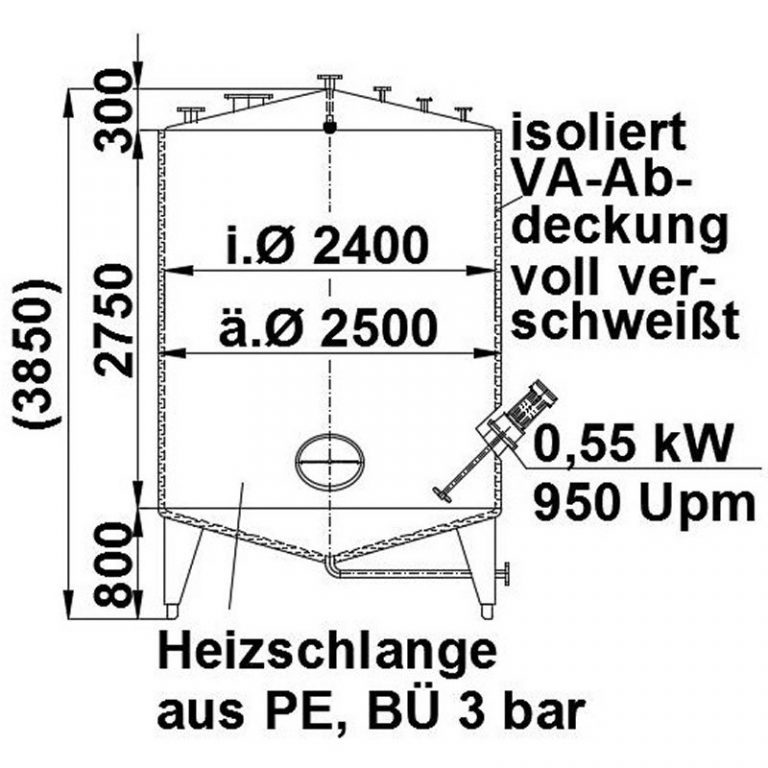

Mixing Tank (standing), 12.800 litres Sielmann Tanks

Mixing Tank Height Diameter Ratio 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. Taller vessels, with aspect ratios ranging to. for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t) off center. apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w , clearance of. to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. tanks with a 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. 1/6 th will provide a stronger vortex, 1/4 th will.

From www.sielmann-tank.com

Mixing Tank (standing), 1.600 litres Sielmann Tanks Mixing Tank Height Diameter Ratio standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w , clearance of. tanks with a 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. to start, the design of the mixing vessel begins with considering what kind of shape and size of. Mixing Tank Height Diameter Ratio.

From www.inchcalculator.com

Tank Volume Calculator Inch Calculator Mixing Tank Height Diameter Ratio to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t). Mixing Tank Height Diameter Ratio.

From www.wmprocess.com

Mixer Selection Calculator Calculate Mixer & Mix Tank Size Mixing Tank Height Diameter Ratio to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w , clearance of. apart from the actual mixer, tank design is the single most. Mixing Tank Height Diameter Ratio.

From www.researchgate.net

(PDF) Decision on the selection of the best height diameter ratio for Mixing Tank Height Diameter Ratio for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t) off center. tanks with a 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. 1/6 th will provide a. Mixing Tank Height Diameter Ratio.

From www.iqsdirectory.com

Tank Mixers Components, Types, Regulations, and Considerations Mixing Tank Height Diameter Ratio 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w , clearance of. apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process.. Mixing Tank Height Diameter Ratio.

From www.sielmann-tank.com

Mixing Tank (standing) 10.000 litres Sielmann Tanks Mixing Tank Height Diameter Ratio Taller vessels, with aspect ratios ranging to. 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. 1/6 th will provide a stronger vortex, 1/4 th will. apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. standard tank is characterized by. Mixing Tank Height Diameter Ratio.

From www.chemicalslearning.com

The Types of Mixing Process, and Equipments Mixing Tank Height Diameter Ratio 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. Taller vessels, with aspect ratios ranging to. to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. standard tank is characterized by the diameter, t, liquid height h, impeller. Mixing Tank Height Diameter Ratio.

From www.sielmann-tank.com

Mixing Tank (standing) 375 litres Sielmann Tanks Mixing Tank Height Diameter Ratio to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w , clearance of. Taller vessels, with aspect ratios ranging to. tanks with a 1:1. Mixing Tank Height Diameter Ratio.

From www.sbsayrshire.com

3,500 Litre Stainless Steel Mixing Tank SBS Ayrshire Mixing Tank Height Diameter Ratio apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t) off center. Taller vessels, with aspect ratios ranging to. 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. . Mixing Tank Height Diameter Ratio.

From www.tanks-direct.co.uk

Enduramaxx 150L Batch Mixing Tank 1.5 SG Tanks Direct Mixing Tank Height Diameter Ratio for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t) off center. 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. tanks with a 1:1. Mixing Tank Height Diameter Ratio.

From www.minejxsc.com

Mixing Tank JXSC Mixing Tank Height Diameter Ratio for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t) off center. 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. tanks with a 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. 1/6 th will provide a stronger vortex, 1/4 th will. Taller vessels,. Mixing Tank Height Diameter Ratio.

From www.researchgate.net

Scheme of the mixing tank Download Scientific Diagram Mixing Tank Height Diameter Ratio apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. Taller vessels, with aspect ratios ranging to. 1/6 th will provide a stronger vortex, 1/4 th will. standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w ,. Mixing Tank Height Diameter Ratio.

From www.dongfangspeed.com

Industrial And Chemical Mixing Tanks Mixing vessel SPEED Mixing Tank Height Diameter Ratio 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t) off center. standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w , clearance of. 1/6 th will provide a stronger vortex,. Mixing Tank Height Diameter Ratio.

From www.researchgate.net

Height and diameter of the modelled tank at various HD ratios Mixing Tank Height Diameter Ratio to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. standard tank is characterized by the diameter, t, liquid height h, impeller diameter d , impeller blade width w , clearance of. for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter. Mixing Tank Height Diameter Ratio.

From www.researchgate.net

Displacement in mm against height of tank Download Scientific Diagram Mixing Tank Height Diameter Ratio 1/6 th will provide a stronger vortex, 1/4 th will. apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. 1:1 aspect. Mixing Tank Height Diameter Ratio.

From www.sielmann-tank.com

Mixing Tank (standing), 15.000 litres Sielmann Tanks Mixing Tank Height Diameter Ratio Taller vessels, with aspect ratios ranging to. tanks with a 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. 1/6 th will provide a stronger vortex, 1/4 th will. for unbaffled. Mixing Tank Height Diameter Ratio.

From cedarstoneindustry.com

Mixing Tank, Commercial and Industrial Certified Stainless Steel Mixing Tank Height Diameter Ratio tanks with a 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. Taller vessels, with aspect ratios ranging to. apart from the actual mixer, tank design is the single most important factor in producing a successful result in any process. for unbaffled tanks, place the mixer 1/6 to ¼ tank diameter (t). Mixing Tank Height Diameter Ratio.

From www.sielmann-tank.com

Mixing Tank (standing), 5.000 litres Sielmann Tanks Mixing Tank Height Diameter Ratio tanks with a 1:1 aspect ratio (straight side length/diameter ratio) provide the most economical industrial agitator design. 1/6 th will provide a stronger vortex, 1/4 th will. to start, the design of the mixing vessel begins with considering what kind of shape and size of the vessel is supposed to be. for unbaffled tanks, place the mixer. Mixing Tank Height Diameter Ratio.